CADCode End-users’ Showcase

Here’s a sampling of what the users of CADCode make with our software. The work shown may include some features created in other software programs or using materials not processed with the CADCode suite of products.

If you’d like to submit samples of your process or your work, we’d be pleased to showcase it.

The newest videos, produced and supplied by Modern Woodcrafts of Plainville, CT, a CADCode user since 2006, feature aspects of the latest additions to their production line: an automated board storage and retrieval system, and automated pre-labeling of panels before they are machined, all supported by their CADCode software.

The videos below, from Northway Industries in Pennsylvania, show three different methods for importing data into CADCode and the many options for processing that then exist. The video from Stevens Industries in Illinois is another example of how we can show off your work. If you have a photographs or a video you'd like us to feature, please let us know.

The video below, from Northway Industries, shows the use of CADCode's MPR reader to import data via the woodWOP/MPR format. Once imported, the user has many options for processing, including nesting, saw optimization, generating code for individual parts, nested parts, and cutting parts on the saw. Part labels and reports can also be generated as additional processes.

This second video from Northway Industries shows the use of CADCode's Mapped Data reader to import data generated on the user's set of Excel spreadsheets. Using the spreadsheet to define what needs to be made, including machining, a .CSV file is created for the job and then imported into CADCode. From there, the full range of CADCode features is available to process the data - to send parts to different machines simultaneously, to do both nested-based and saw+point-to-point machining, etc., again, all simultaneously, if so desired.

This video, also created by Northway Industries, shows the use of AutoCAD and CADCode's AutoCAD Reader (also known as ACAM) to create drawings, assign layers and machining, export to CADcode for processing where the parts can be assigned to be manufactured on a saw or in a nest, machinined on one or many CNC machines, and to generate the code, reports and labels needed for the job. With the AutoCAD Reader, the user can make edits to the part directly in AutoCAD without modifying the original drawing (if so desired).

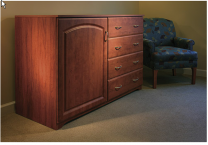

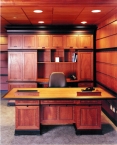

This video, created by Stevens Industries, showcases their casework and industrial cabinetry, much of which they create with the use of CADCode software.

To zoom in on an image, just click on it. A slide show will start automatically after a slight pause.

- Login to post comments